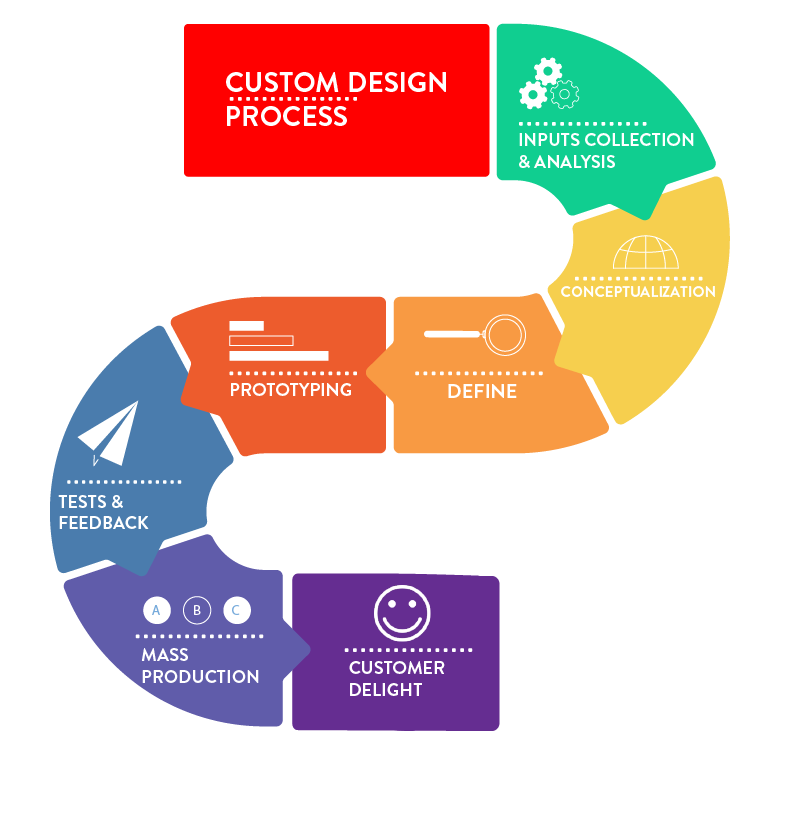

Custom Design Process

Inputs Collection & Analysis

Inputs Collection & Analysis

We Thoroughly Collect And Analyze The Requirements Defined By Our Customer.

Conceptualization

We Formulate A Technical Proposal Based On Defined Electrical Performance, Mechanical Dimensions, Certification/approvals Required And Cost Constraints, If Any.

Define

Quote Submitted As Per MOQ Required By Customer Along With Commercials & Lead Time For Prototype & Production Order.

Prototyping/ Sampling

Quick Development Of Prototypes Or Samples For Basic, Functional And Application Testing And Eventual Homologation. In Case The Custom Solution Needs Customized Plastics – New Tooling Is Developed At This Stage Before Building Samples. A Complete Technical Data Sheet Of The Developed Component Is Submitted Along With Samples At This Stage.

Tests Feedback

Based On The Tests Feedback The Design Is Either Released For Pilot Lot Production Or Improvised Further Based On Observations During Testing. In Cases, Where Certain Improvements Are Desired In The Component Design By The Application Engineer, New Samples Are Developed And Submitted For Testing Again.

Pilot Lot

With The Technical Release On Samples And Data Sheet, A Small Lot Of 50 To 1000 Pcs Is Produced On The Main Production Lines. During Production Of Pilot Lot, Our Production & Quality Processes Are Fine-tuned And Improvised To Meet The Specificity Of The New Developed Component. Various Component Specific Documents Are Made At This Stage For Future Mass Production. The Produced Pilot Lot Is Then Delivered To Customer For Final Tests.

Mass Production And Deliveries

With The Successful Testing Of Pilot Lot At Customer End, The New Developed Component Is Then Fully Released For Mass Production. We Then Ensure That The Ordered Components Are Delivered As Per The Agreed Schedule Only.

Customer Delight

And Then Begins The Journey From Customer Satisfaction To Customer Delight. This Is The Stage To Fulfill The Basic Promise – Right Material At Right Price In Right Time. We Strive To Keep This Promise With Proactive And Easy Communication With Our Customers.

Why this is the best custom design approach?

- It is a transparent system and avoids any misunderstanding / issues for later stages

- Clarity on design requirements and deliverables is established at the initial stage itself

- The clarity is well maintained throughout the development cycle

- The clarity & communication enables effective & fast solutions even for complex requirements

- Very short overall development time enables short time to market for application

- No hiccups or issues once the project reaches ramp-up stage